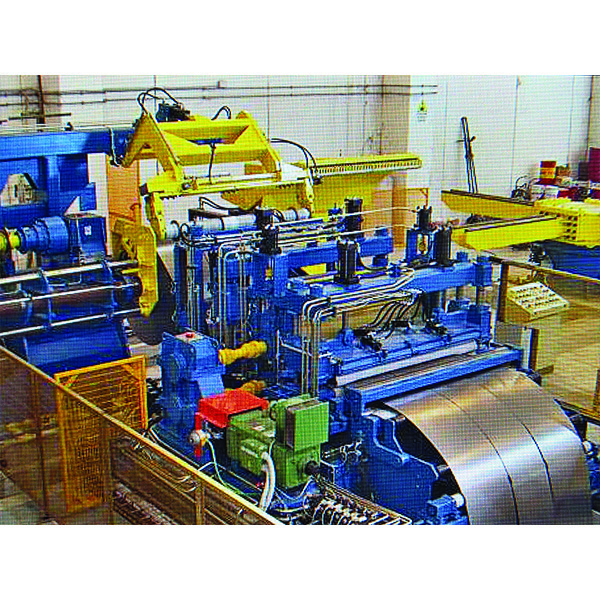

SLITTING COIL LINE CTL-3-6-9-12-16-2000

Our Slitting lines are designed with the latest standards of technology and completely made in our factory. Our Slitting lines can be used for processing hot and cold-rolled galvanized, pre-painted and stainless steel coils, as well as nonferrous materials - aluminium, copper and brass coils.Our designers develop all the new projects according to the customer needs and requirements, so all our lines are customized according to the individual requirements.Our slitting lines use the most advanced quick –change tooling systems where manual operations are minimized that allows our customers to minimize the tooling change time as well. The advanced technology of our slitting lines allows to provide an excellent quality of coils slitting as well as tight and flat strip recoiling after slitting. Our lines are equipped with the latest generation of control systems and automatization according to our customers needs and requirements.

Material thickness from 0,3 mm TO 16 mm, max coil width 2100 mm, max coil weigth 40 t., max line speed 500 m/min

Configuration example of Slitting Coil Line SL 0.4 to 4 mm width 1600

- Loading Coil Chair

- Purpose; lift and transport coil 20 ton to the Decoiler

- Mobile stand with hydraulic motor, Lifting with hydraulic cylinder

- Containment device for narrow coil

- Loading from the overhead crane directly on the loading chair

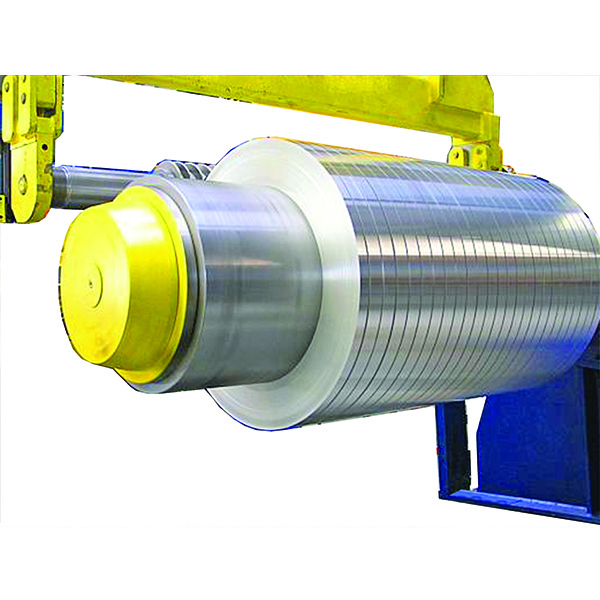

- Motorized Decoiler 20 ton

- Purpose; carry out the previously prepared coil on the chair

- Decoiler 20 ton cantilever Spindle ramps hydraulic expansion

- A.C. gearmotor for introduction phase with braking function during the working phase

- hydraulic pressure arm with motorized roller to band introduction

- Reel translatable forward-backward for the loading coils and for dynamic alignment to keep the line

- Emergency brake disck

- Pinch-Roll Introduction with telescopic table

- It aims to accompany the tape from Decoiler to the Straightener

- Telescopic table width 1650 mm

- 2 motorized rollers 150 mm diameter

- STRAIGHTENER

- Purpose; straighten the cold rolled strip coil by reducing the memory

- No. 5 work roll diameter 150 mm 3 lower 2 upper

- Adjustment of the top roller 2 via the jacks

- Opening of the upper rollers by hydraulic cylinders

- These rollers work only being introduced tape

- During the work phase, the rollers remain open

- Crop Shear

- In order to remove the head and tail of the coil

- Controlled by hydraulic cylinders

- In the phase of Automatic Shear remains open 200 mm

- Adjustable centering rollers

- Evacuation of scraps with conveyor

- Pinch-Roll with rubber rollers

- To pull the tape and send it to the slitter head

- It is placed before the slitter head

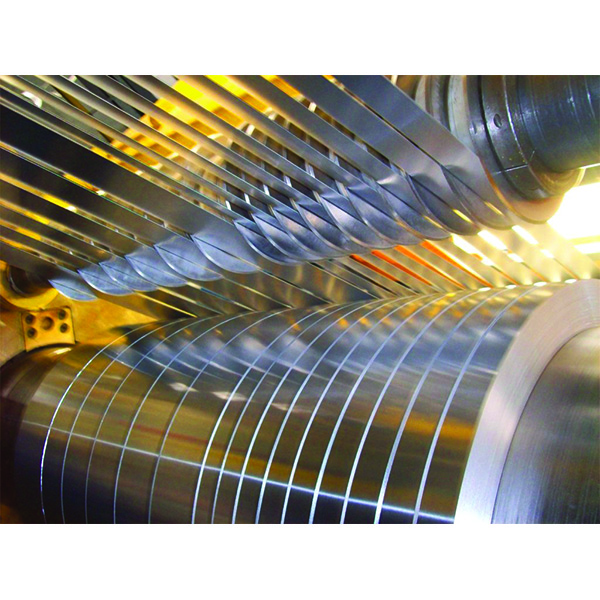

- Fixed Circular shears

- Purpose, cut the tape lengthwise to get the strips planned

- Shaft diameter 250 mm

- Diameter of the cutting blades 320 mm

- No 12 + 12 blades depending on the width to be obtained

- The penetration of the cutting blades is motorized and programmable

- Pinch-Roll pressing side bad borders

- Scrap rewinider on both sides

- Loop control and Loader Bridge Tables

- Braking unit, mobile or land with riding output rollers

- Press Felt, Pass-line roller Roller deflector and Table

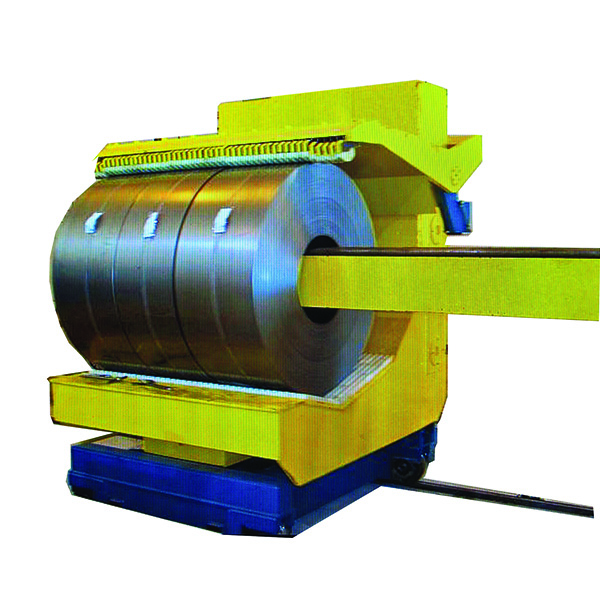

- Winder reel with arm Separators

- Downloading car

- Carousel with 4 arms

- Electrical and Electronic Equipment

- A.C. and D.C. motor drive according to the machinery

- PLC SIEMENS S7

- Separate Cabinet for Servo Drivers

- Separate Cabinet for programmable logic Control

- Pulpits and mobile pushbutton for manual controls

- Hydraulic equipment

- Purpose ; Provide the hydraulic power cylinders and hydraulic motors

- Consisting of 400 liter tank with pump 90 liters / minute at 120 bar

- Safety valves and sequence valves

- of care have indicator and oil level indicator

- series of solenoid valves 24 VDC Athos

- Heat exchanger

- Pneumatic equipment

- Working pressure 6 bar

- Lubrication of filter groups, pressure regulators and relative pressure gauges

- The compressor machine it is not included

- The machine is self-certified CE and is covered by warranty for 12 months

The machine is equipped Instruction Manual, Safety Manual, CE Certificate